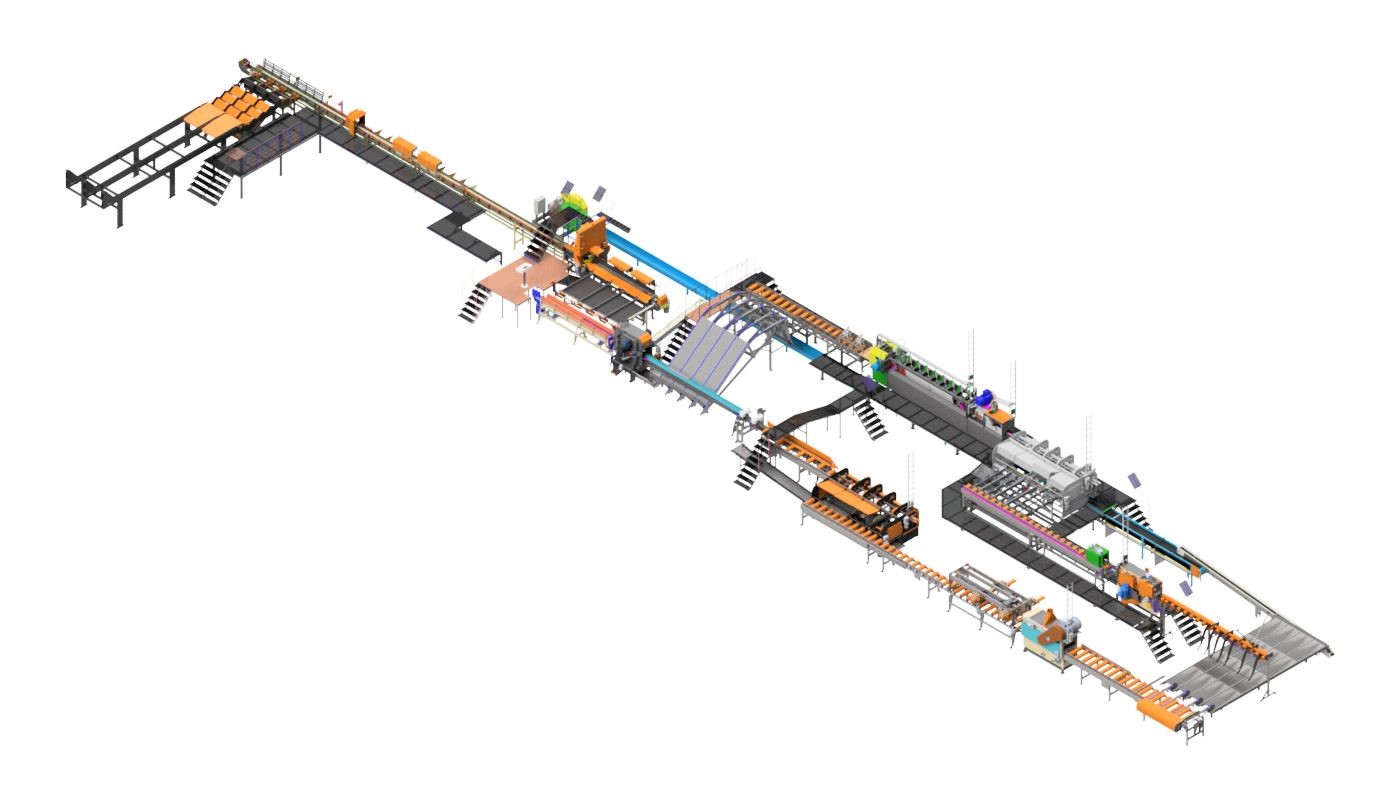

UMG 801.25 Automatic pallet board production line

The line is designed for the preparation of boards for the production of Euro pallets (pallets) from softwood and deciduous wood. The line is capable of performing the full scope of technological operations from sawing a round log to finished boards of the required size for the production of Euro pallets (pallets). The line consists of three main blocks: the main block for cutting logs into boards, a block for cutting slabs into boards, a block for collecting and moving sawdust, lump waste to a waste grinder.

| Parameters | |

| Energy sources | Electricity max. 820 kW |

| Parameters of the workpiece in mm. | |

| Length | From 2450 to 6200 |

| Thicknes | From 120 to 380 |

| Dimensions of the board in mm. | |

| Length | From 1000 to 6200 |

| Width | From 75 to 150 |

| Thickness | 12 |

| Average line productivity (for logs with a thickness of 180-240 mm. and a curvature of no more than 1%), m³/m | Until 18,75 |

| Capacity of ramps for logs, m³ | Until 20 |

| Management | Automatically from the operator console |

| Working employees (one work shift) | 2 operators and 4 packers |

| Minimum area | Length 100 m, width 22 m. |